Hi everyone!

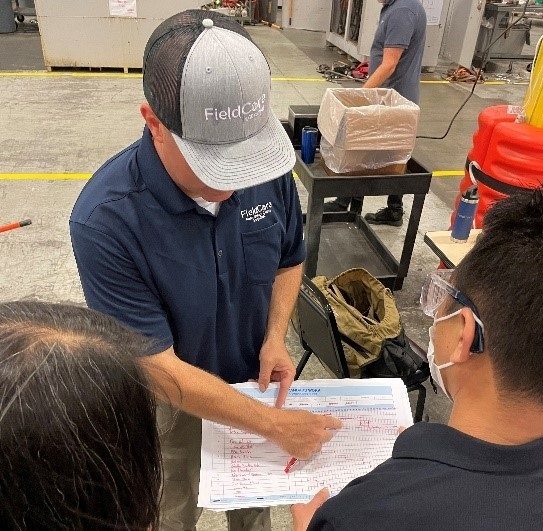

A few weeks ago, I was lucky to be part of FieldCore’s first ever Tooling Shingi Lean event at the Atlanta Tool Center. Five action-oriented teams joined multiple Kaizen events to develop lean solutions for specific challenges faced in the Tool Center and within our overall FieldCore organization.

For those of you that may not be familiar with Lean, a Shingi event is basically multiple, simultaneous Kaizens (continuous improvement) conducted at one time with the goal of rapidly improving many processes. Under the guidance of a Lean Sensei (teacher) from the Shingijutsu company, teams will work together to find more effective solutions to various processes and procedures. With this event comes the expectation that on the Monday following, we’ve changed the way we work and we’re running our operations or processes differently.

For those of you that may not be familiar with Lean, a Shingi event is basically multiple, simultaneous Kaizens (continuous improvement) conducted at one time with the goal of rapidly improving many processes. Under the guidance of a Lean Sensei (teacher) from the Shingijutsu company, teams will work together to find more effective solutions to various processes and procedures. With this event comes the expectation that on the Monday following, we’ve changed the way we work and we’re running our operations or processes differently.

During these five days, over 50 people across FieldCore, GE Gas Power and APM worked side by side to apply lean solutions to the specific challenges they face to rapidly resupply our teams in the field. From large toolkits for Gas turbines to Live Outage kits, their hard work led to amazing progress in reducing the re-kitting time by more than 50%. This dramatically improved the Tool Centers’ efficiency and our ability to support our Field Teams on the front line and in the end our customers.

It was incredible to witness the journey of each team as they went into the unknown, worked the art of the possible and came out so encouraged and proud of what they accomplished. From nervousness and skepticism to acceptance, I watched the teams push themselves out of their comfort zone, realizing change rarely happens when we embrace status quo.

It was incredible to witness the journey of each team as they went into the unknown, worked the art of the possible and came out so encouraged and proud of what they accomplished. From nervousness and skepticism to acceptance, I watched the teams push themselves out of their comfort zone, realizing change rarely happens when we embrace status quo.

One of the best parts about executing a Shingi is having the opportunity to spend time and learn from a Sensei, whose main purpose is helping companies achieve Lean production. Our Sensei, Hosokura-san, took this experience to a whole new level by pushing us to try, keep trying and then try again until we came up with an efficient enough solution that would bring the expected (or more) target outcomes we set. He challenged every decision the teams took by asking them to really look past the obvious and focus on truly eliminating waste. He reminded us that both “creativity and ideas are free” and we should always be open to all options when approaching a problem.

As I reflect on our first tooling Shingi event, I further appreciate the need to go to Gemba, the importance of listening to our teams on the front-line and for everyone to roll up our collective sleeves to make change to the way we work. I’m confident we’ll achieve remarkable results that help pave way for us to be a truly Lean organization, with a focus on our customers as we strive to deliver World-Class Execution.

This experience was amazing to say the least. We collectively were able to experience a real game changer here at FieldCore and I am so proud of everyone that made this Shingi a success. This is just step one in a long journey that we have in front of us. I can’t wait to see what our next Lean adventure will be and how we transform the way we deliver tooling for years to come!

Cheers,

Jim