FieldCore’s Aeroderivatives team in Italy is bringing next-generation technology to confined space inspections with drones.

At every level of the organization, we strive to find solutions that make work safer for employees, while delivering World-Class execution for our customers. Antonio Artusato, Aero Service Manager, Italy, was seeking ways to be more simple, nimble and fast, and make work safer for employees during a recent outage. That’s when he had the idea to conduct a pilot test using a drone for a confined space inspection.

Working with the Alpha Robotix Drone Solutions company, Antonio and his team recently conducted the first FieldCore drone inspection of an Aero exhaust / inlet/ filter room at a Power Plant in Italy.

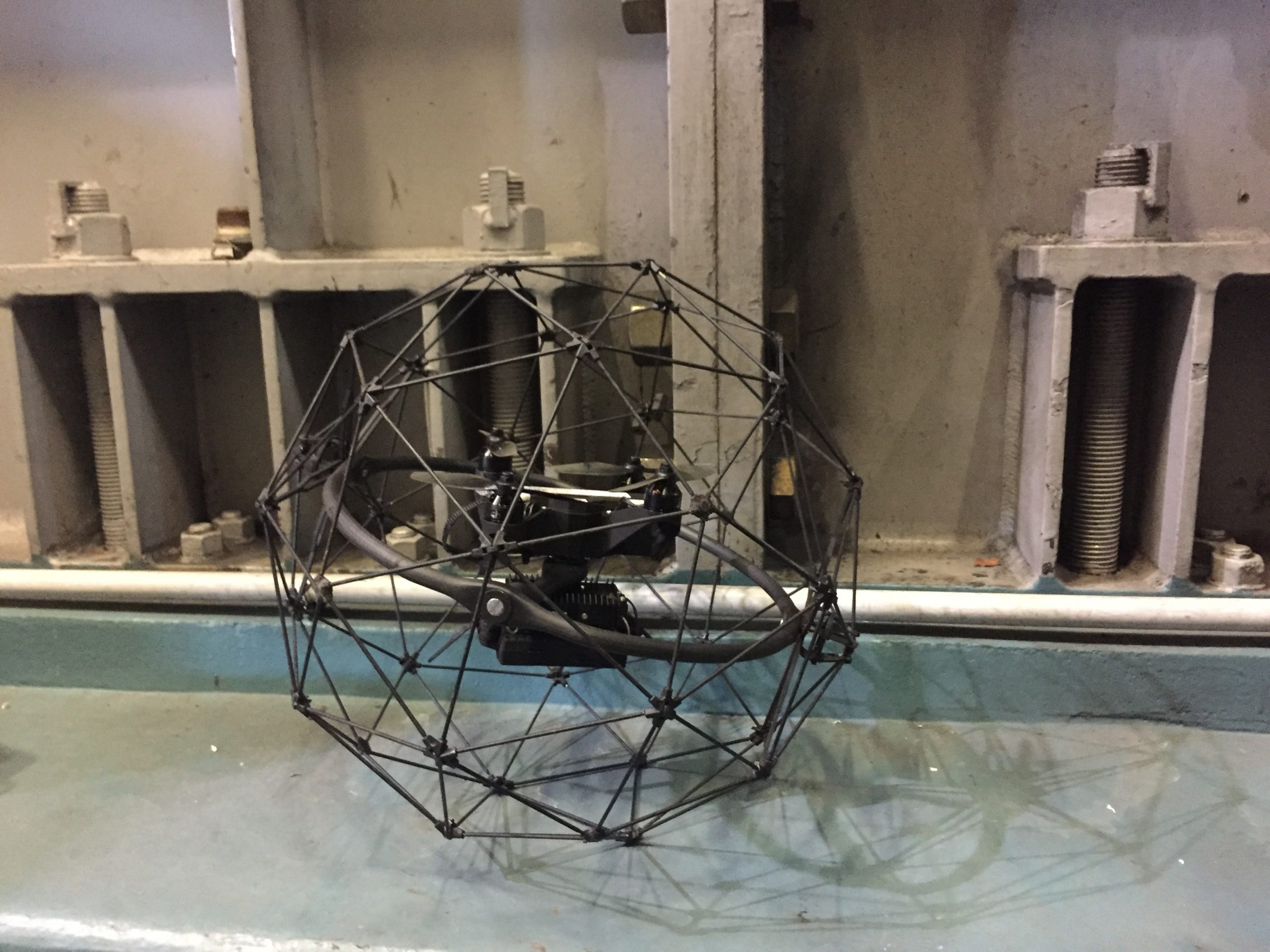

For their test, they used an Elios ‘ball’ drone. This type of drone has gyroscope technology and is outfitted with a special carbon-fiber cage designed to protect the drone and to eliminate any damage it might cause to the equipment if it bumps into something.

As a trained Alpha Robotix pilot operates the drone, a FieldCore Aero Field Engineer assists, providing directions and instructing the pilot which way to go so that we collect all the information we need. Because of the tight spaces the drones are flying into, it requires a highly skilled operator to maneuver it through the space.

During the inspection, the drone pilot and the FieldCore expert can view a live video feed to give an assessment of the conditions in the space under inspection. The video is also recorded and can be saved for closer viewing later. Onboard the drone is a full HD thermal camera, and LED lights which allow the drone to effectively inspect spaces even in pitch-dark environments, collecting valuable information that would not be available to the human eye. The drone’s small size allows it to enter and inspect confined spaces as small as a manhole.

Besides making work safer for employees, customers also benefit with significant time savings.

“Usually, a typical inspection of this sort without using drones could take up to three hours and require four employees,” said Petrino Ferrara, Service Director.

By conducting the inspection with a drone, we can significantly reduce the inspection time while keeping our people safe..”

Petrino explains that Italy was the perfect choice for the test program because of stringent requirements for people entering confined spaces to conduct inspections.

Antonio adds that customer feedback has been very positive. Customers have been impressed by the ingenuity of FieldCore to explore this technology and appreciate that we are working to eliminate risks to employees on the job while also saving critical time during inspections.