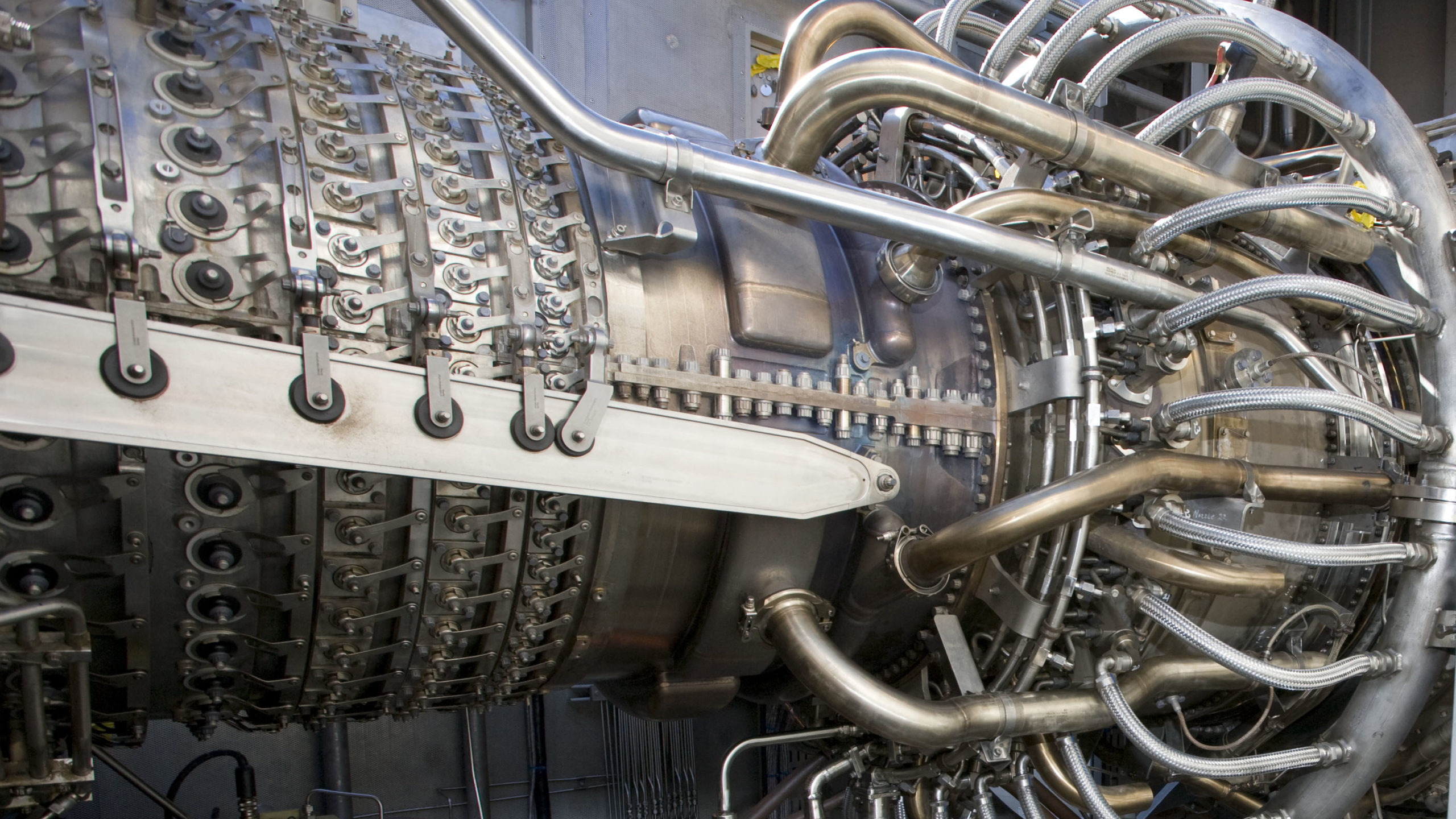

The Kwinana Power Station which is located in Perth, Western Australia was part of an expansion project in 2009 to include the installation of two General Electric (GE) LMS100 turbines. LMS100 is design based on heavy-duty frame gas and aero-derivative gas turbines. It is the first intercooled gas turbine system designed by GE especially for the power generation industry. The turbines have dual fuel capability (gas and oil) and provide additional capacity to help Contact Energy maintain a constant and regular supply of electricity in Western Australia.

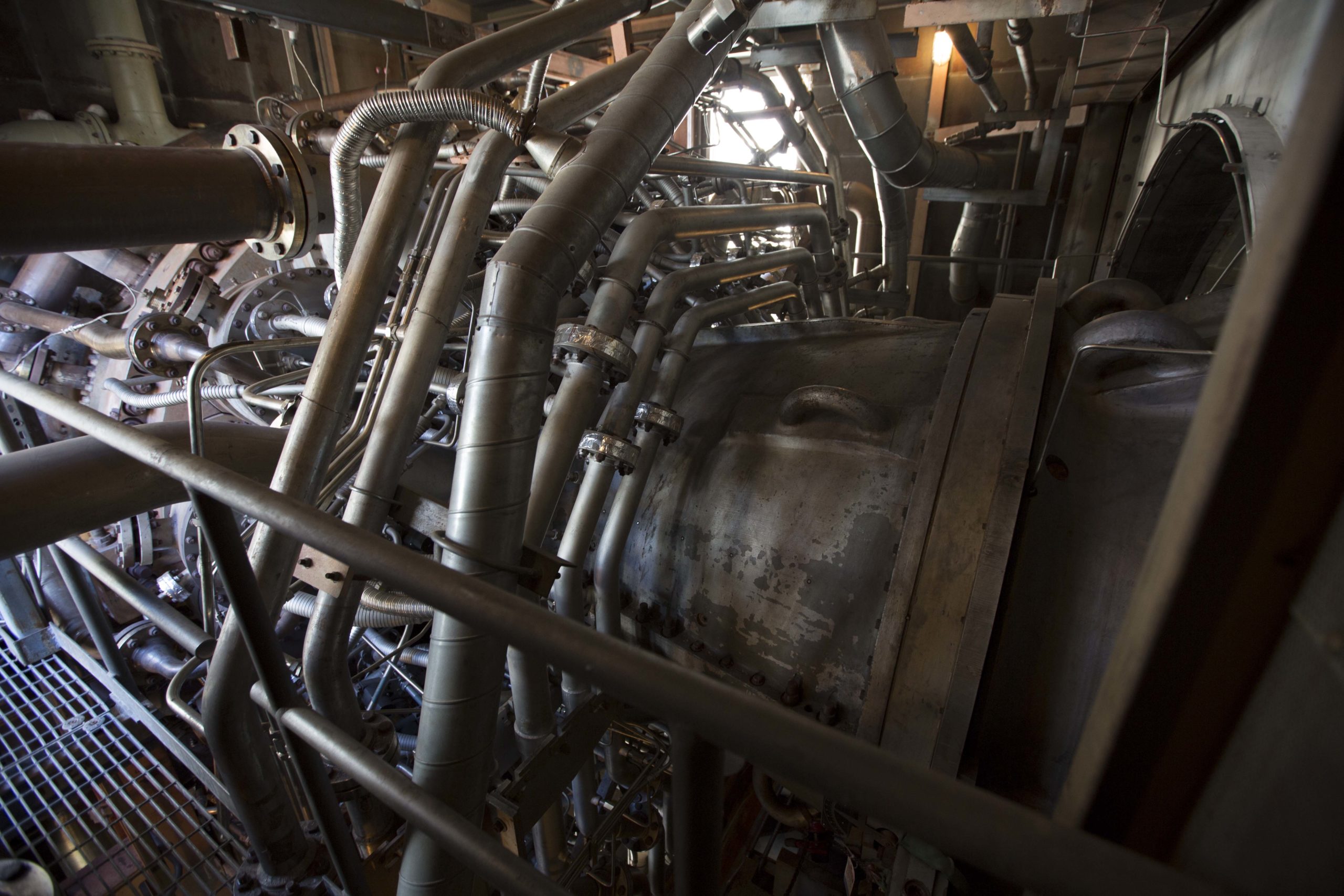

FieldCore has been part of the execution team taking care of the maintenance of these LMS100 units at Kwinana. In the last quarter of 2018 as part of an unplanned outage, the LMS100 engine suffered serious issues of alignment and the engine was down for a considerable time.

The FieldCore Aeroderivative team, led by a highly experienced outage manager successfully resolved the issues within a tight timeline that was given by the customer. The team received appreciation letters from the customer, having not only met but exceeded expectations making it an efficient and smooth outage. What stood out was the swift and accurate troubleshooting that was carried out on a short notice availability during the forced outage.

The FieldCore Aeroderivative team, led by a highly experienced outage manager successfully resolved the issues within a tight timeline that was given by the customer. The team received appreciation letters from the customer, having not only met but exceeded expectations making it an efficient and smooth outage. What stood out was the swift and accurate troubleshooting that was carried out on a short notice availability during the forced outage.

In November 2019, there was another work scope for a multiple complex alignment issue. A team of five FieldCore services representatives worked on these critical scopes – alignment, hot section exchange and IPT change outs. The key value that FieldCore was able to add to contribute to a successful outage was the quality of workmanship, outage preparedness and a seamless on-time execution.